5 QUESTIONS TO ASK WHEN BUYING A TANK

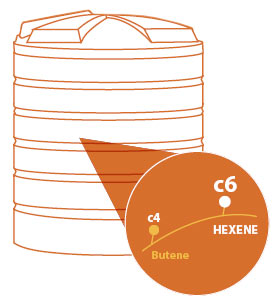

02. What type of comonomer used?

The comonomer forms branches in the polymer chain and the longer the branch the tougher the material.

Alkatuff uses a hexene (C6) co-monomer with a branch length double that of a regular butene (C4) co-monomer. For exceptional long-term performance, opt for a tank with a C6 co-monomer.

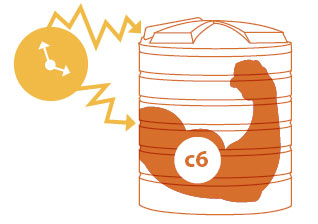

03. Does it offer a high level of creep resistance?

Materials can deform permanently over time when subjected to high temperatures and mechanical stresses. A material’s ability to withstand these pressures is known as its “creep resistance”. In water tanks creep mostly manifests as “bulging”.

Alkatuff polyethylene enables the production of tanks with excellent creep resistance due to its C6 co-monomer which provides superior toughness.

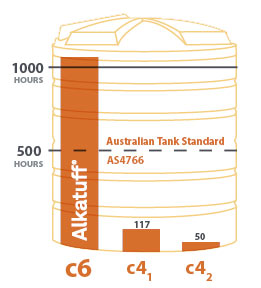

04. Does it have superior environmental stress crack resistance (ESCR)?

AS/NZS 4766 defines the performance for polyethylene tanks storing water and chemicals and requires that the tank material survives 500 hours of exposure to a harsh reagent without failure due to cracking.

Alkatuff polyethylene offers an ESCR performance of over 1,000 hours ensuring years of reliable service.

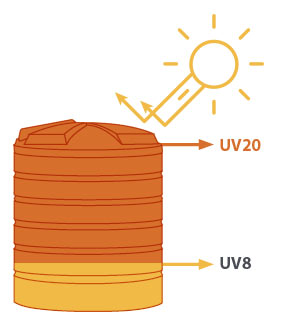

05. Is it built to withstand Australian conditions?

From sub-zero mornings to the unrelenting outback sun, Australia has some of the planet’s most extreme climate conditions.

Australian made tanks built from Alkatuff have proven long term performance in Australia’s tough conditions.